SILVER ELECTROLYTIC REFINING

The silver electrolytic refining method works properly if the minimum silver content in the alloy is 800/1000.

The silver purity yield at the end of the process is of 999/1000.

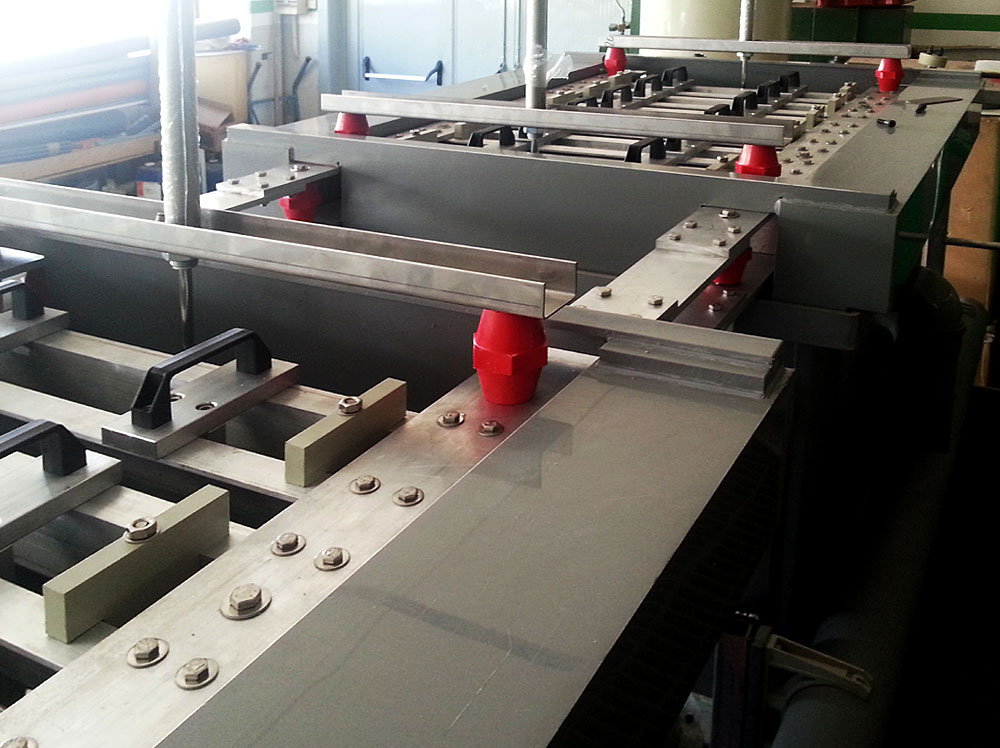

The silver electrolytic refining plants are modular and able to cover a wide range of production requirements.

MAIN CHARACTERISTICS:

- Modular systems;

- Wide choice of models and construction materials according to installation and working requirements;

- Capacity (on a daily basis production): from 15 to 180kg and more;

- Unsupervised 24h operational cycles;

- Limited maintenance required;

- Possibility to recover side metals as residual of the electrolytic process (anodic sludge);

- Flexibility to operate with limited working load.

|

|

|

| Model | BT-ELTR-AG-30 | BT-ELTR-AG-60 |

| Electrolytic cell features | 1 raised cell with discharge | 2 raised cells with discharge |

| Input material | Min 12 kg (1 anode) Max 144 kg (12 anodes) |

Min 12 kg (1 anode) Max 288 kg (24 anodes) |

| Input Ag quality | Min 800/1000 | |

| Max production capacity | 30 kg | 60 kg |

| Output Ag quality | 999/1000 | |

We realize systems composed of more than 2 electrolytic cells, on project, based on the operational and installation needs of the Customer.

In addition to the electrolytic cells, we are able to supply accessory plants such as the electrolyte preparation reactor (AgNO3), silver crystal washing and filtration systems with steel barrel for large productions, silver recovery plants from exhausted electrolytic, casting tables anodes of silver and molds for anodes.

Our technical staff is available to guide the customer in choosing the most suitable system for his needs.

Interested? Contact us for info.

Balestri Technologies S.r.l.

Balestri Technologies S.r.l.